In recent years, with the development of the automobile industry, the world's automobile production and increasing ownership. China's automobile industry by leaps and bounds in 2009, automobile production and sales of more than 1,300 million, more than the United States and Japan to become the world's automobile production and sales superpower. Car travel convenience to people and also produces fuel consumption, environmental protection and safety of the three problems. Focusing on sustainable development considerations, lower fuel consumption and reduced emissions of pollution is particularly urgent. According to authoritative statistics international motor vehicle fuel consumption by about 60% in vehicle weight. Each car lighten the weight of 10%, emissions can be reduced by 10%, can reduce fuel consumption by 7%. Thus, the automobile weight loss, weight is an effective measure to achieve the above objectives.

Automotive lightweight way to realize there are mainly two: First, optimize the car frame structure; the other is the use of lightweight materials in the automotive manufacturing. Light alloy currently used on automobiles are mainly aluminum, magnesium, titanium alloy sheet and the like.

Titanium applications and features in the car

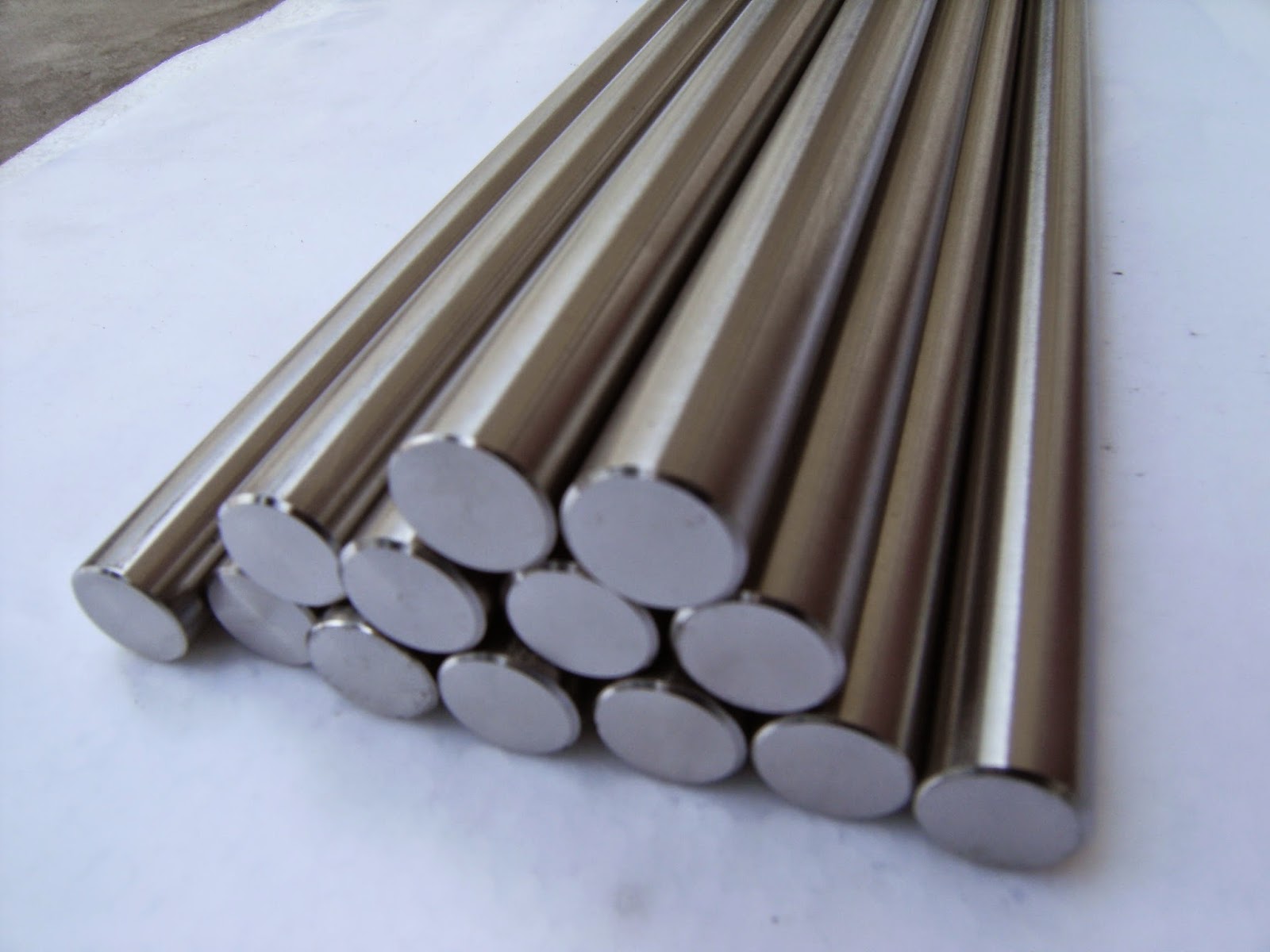

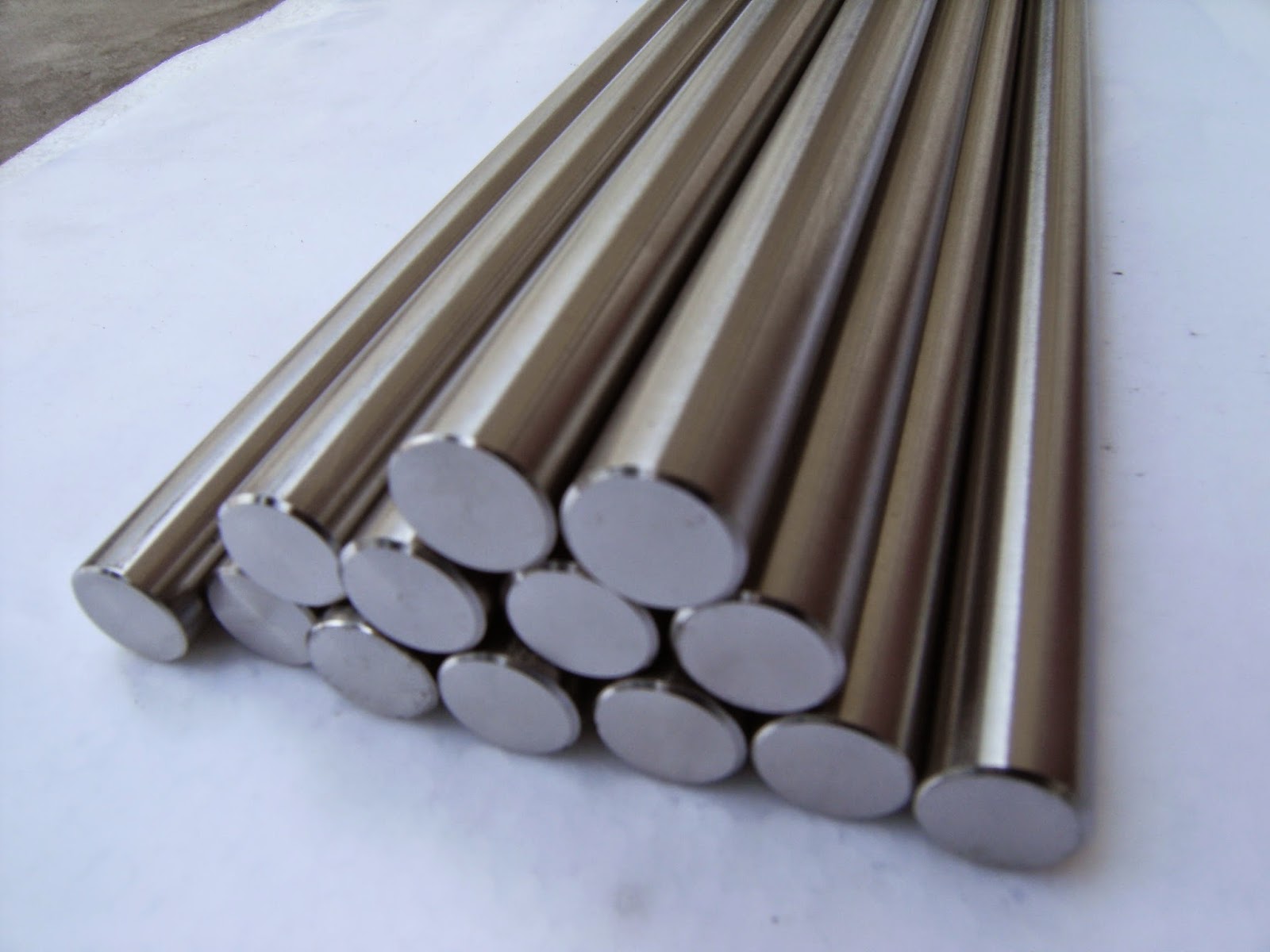

Titanium is a new structural and functional materials, it has excellent overall performance, density, high specific strength. Density of titanium was 4.51g / cm3, interposed between the aluminum (2.7g / cm3) and iron (7.6g / cm3). Higher than the strength of the titanium alloy aluminum and steel, toughness and steel quite. Titanium and titanium alloy corrosion performance is good, better than stainless steel, particularly resistant to corrosion and micro-oxidizing atmosphere under chloride ion corrosion resistance in the marine atmosphere, a wide operating temperature titanium alloys, titanium alloys at low temperature -253 ℃ but also to maintain good ductility, and heat-resistant alloy operating temperature up to about 550 ℃, its heat resistance was significantly higher than that of aluminum and magnesium alloys. Also has good workability, weldability.

Titanium and titanium alloy Ti excellent performance since the industrial production on various tech industries much attention, along with the titanium industry started in the mid-1950s, titanium into the automotive industry. Into the 1990s, with the worldwide shortage of energy and enhance the awareness of environmental protection, especially in the automotive industry, the US, Japan and Europe and other countries have issued a series of ecological regulations on fuel efficiency, CO2 emissions, vehicle weight, automobile safety, reliability and put forward higher requirements. Many developed countries and the famous car manufacturers are actively developing and increasing investment in automotive research titanium. Provided a powerful impetus for the car with titanium. Entering the new century, China's titanium alloy bar industry has gradually entered the automotive sector.

In the current automotive market, with luxury cars, sports cars and racing demand increases every year, Titanium components also increased year by year. 1990 Global Automotive titanium is only about 50 tons / year in 1997 to 500 tons / year in 2002 to 1100 tons / year in 2009 to 3000 tons / year. Thus, the automotive industry with titanium into the acceleration phase.

Titanium components used in automobiles

The use of titanium in the car two main categories, the first category is used to reduce the quality of internal combustion reciprocating member (for reciprocating internal combustion engine parts in terms of reducing even a few grams of quality are important); the second category is used to reduce the total mass of the car. According to the design and the material properties of titanium on the new generation of vehicles mainly in the engine components and chassis components. In the engine system, can produce titanium alloys valves, valve springs, valve springs and connecting rod bearing and other components; chassis components primarily for springs, exhaust system, axle and fasteners.

According to information, in addition to the above cited focus, there are: Rocker engine parts, suspension springs, piston pin, turbocharger rotor, fasteners, lug nuts, bumper brackets, door broke into the beam, brake caliper piston, the pin bolt, the clutch disc, the pressure plate, the shift button, and so on.

an alloy containing a certain amount of the element α stable α phase equilibrium composition mainly composed of α-phase. α alloy proportion of small, good heat resistance, good weldability and excellent corrosion resistance, the disadvantage is the low temperature strength, and corrosion resistant material commonly used as the material.

2014年12月31日星期三

2014年12月28日星期日

Medical titanium alloy patented technology status and development trend

Medical titanium alloy patented technology status and development trend

Chinese patent application status

There are in Chinese patent database 209 patent application relates to materials and surface modification of medical grade titanium alloy body medical fields, including domestic applicants (including Hong Kong, Macao and Taiwan) 188 patent applications, foreign patent applicant patent applications 21. Development trends in the Chinese patent application, the number of applications for domestic applicants accounted for the majority of total applications, and the number of applications showed a rising trend, from 2008 to 2009 financial crisis did not cause the recession enterprises decreased emphasis on intellectual property rights, on the contrary, an increase in the number of applications proved enterprises to improve the degree of importance of intellectual property. China submitted a patent application to foreign companies, mainly from Sweden, the United States and Germany and other countries, of which 3% of the total filings in Sweden, 2% of the total US filings, relatively few applications in other countries. Foreign applicants have not carried out a medical patent portfolio in the field of China's titanium, domestic applicants should seize the opportunity to increase research and development in the field of medical titanium alloy, and make patent portfolio.

Global patent application status quo

A total of 1362 relates to the field of surface modification of medical materials and bulk titanium patent applications in European patent database. Medical Titanium appeared earlier patent applications, but the number of applications of slow growth, and in 1993, 2003, 2007 to 2009 peak emerged. The reason is mainly due to new technology at different stages of development will encounter bottlenecks in the development, to solve the bottleneck problem in the number of patent applications will surge. Overall, the number of patent applications increasing medical titanium alloy, titanium medical research institutions in the field of investment is also increasing. States have submitted a patent application in the field of medical titanium alloy, the number of applications for the top six countries were the United States, Sweden, China, Germany, Japan, Switzerland, but the gap between the former six small, indicating that various countries have research and development are very seriously. Chinese applicants filed patent applications accounted for 15% of total patent applications, ranked No. 3, and No. 1 in the United States and Sweden or less, indicating that China rapid development momentum in the field of medical titanium. Due to the presence of biocompatible titanium medical, biological activity, corrosion resistance, wear resistance, mechanical properties and other characteristics in practical applications, in order to improve the performance of the above medical titanium alloy, mainly from the material body of technical means to begin to develop excellent properties of the new titanium; starting from the surface of the material, the use of various surface treatment methods for surface modification of titanium alloy, making it more suitable for medical applications.

2014年12月25日星期四

Growth in the fast lane into the car with titanium

Titanium is a new structural and functional materials, it has excellent overall performance, density, high specific strength. Higher than the strength of the titanium alloy aluminum and steel, toughness and steel quite. Titanium and titanium alloy corrosion performance is good, better than stainless steel, particularly resistant to corrosion and micro-oxidizing atmosphere under chloride ion corrosion resistance in the marine atmosphere, a wide operating temperature titanium alloys, grade 2 titanium alloys at low temperature -253 ℃ but also to maintain good plasticity, and heat-resistant alloy operating temperature up to about 550 ℃, its heat resistance was significantly higher than that of aluminum and magnesium alloys, but also has good workability, weldability.

Titanium and titanium alloy Ti excellent performance since the industrial production on various tech industries much attention, along with the titanium industry started in the mid-1950s, titanium into the automotive industry. Into the 1990s, with the worldwide shortage of energy and people's awareness of environmental protection, especially in the automotive industry, the US, Japan and Europe and other countries have issued a series of ecological regulations, fuel rate, carbon dioxide emissions, vehicle weight, automobile safety, reliability and put forward higher requirements. Many developed countries and the famous car manufacturers are actively developing and increasing the use of Ti in terms of automotive investment, provided a powerful impetus for the car with titanium.

In the current automotive market, with luxury cars, sports cars and racing demand increases every year, Titanium components also increased year by year. 1990 Global Automotive titanium tubing is only about 50 tons / year in 1997 to 500 tons / year in 2002 to 1100 tons / year in 2009 to 3000 tons / year, next year will also maintain double-digit growth Thus, the automotive industry with titanium into accelerated growth phase.

2014年12月21日星期日

Titanium applications in our military aircraft engines

With WP-13 series engines did not count stereotypes, engine production jump yields also increased, to 1990 WP a J3 series engine with titanium has more than lOGt, titanium alloy sheet plant in the company amounted to eliminate the sale of more than 18 million yuan. Therefore, WP-13 series engines bulk titanium for our dirty air engine has accumulated flying experience, and promote China's aviation titanium.

Aerospace from the early 1970s on the aeroengine conducted pre-research work Titanium application, after 16 years of hard work to make TCl, TC2A, TC4, TCS, TC11, TA6, TA7, ZT4, ZT3 total of nine brands the elimination of the alloy used WP-7B (BM), the WP-13 and four modified engines, so that our aviation engine into the production phase of titanium and has effect subject to a variety of night flight test.

To meet the needs Jian Qi an M-type aircraft, for WP-7B engine improvements designed to ensure that the aircraft balance, resulting in the afterburner section, weight 17kg. In addition to weight reduction measures taken by the structure did not count, but also the use of grade 1 titanium sheet and titanium alloys replace some stainless knot 抅 titanium, which is an important means to reduce the weight of the engine. Therefore, in the WP-tBcbm engine afterburner parts department with a total of 22 four grades of titanium, titanium single quota for 59.47kg.

The launch ridiculed in 1982 by the Ministry of Aviation Industry technical appraisal and loquat into mass production, some of which were exported. As of 1990, the total production of the engine hundreds, titanium has more than 30t, with sales of 5.4 million yuan titanium plant. Volume applications of titanium alloys for aircraft engine company exports worth more than $ two 丨 B. It is worth noting that the actuator cylinder engine afterburner ashamed TC6 alloy by using isothermal forging of thin-walled hollow forgings, is the earliest use of aero engine isothermal forging of large bearing parts for our titanium alloys in aircraft engines application accumulated practical experience. The machine has developed five types of engines, using nine grades of titanium seamless pipe, titanium alloys used in China is currently the most burning aircraft. From the use of titanium level analysis, TCll (BT9), ZT3 is heat resistant alloy 500 long-term use of it, up to the international level in the early 1980s. From the engine with titanium content 'points off, Titanium Pan zero weight of the total weight accounted for 14% of the engine, the engine is a single titanium quotas were 855kg and 1055kg, is China's current production of aviation engines loquat amount up to the amount of titanium models .

Aerospace from the early 1970s on the aeroengine conducted pre-research work Titanium application, after 16 years of hard work to make TCl, TC2A, TC4, TCS, TC11, TA6, TA7, ZT4, ZT3 total of nine brands the elimination of the alloy used WP-7B (BM), the WP-13 and four modified engines, so that our aviation engine into the production phase of titanium and has effect subject to a variety of night flight test.

To meet the needs Jian Qi an M-type aircraft, for WP-7B engine improvements designed to ensure that the aircraft balance, resulting in the afterburner section, weight 17kg. In addition to weight reduction measures taken by the structure did not count, but also the use of grade 1 titanium sheet and titanium alloys replace some stainless knot 抅 titanium, which is an important means to reduce the weight of the engine. Therefore, in the WP-tBcbm engine afterburner parts department with a total of 22 four grades of titanium, titanium single quota for 59.47kg.

The launch ridiculed in 1982 by the Ministry of Aviation Industry technical appraisal and loquat into mass production, some of which were exported. As of 1990, the total production of the engine hundreds, titanium has more than 30t, with sales of 5.4 million yuan titanium plant. Volume applications of titanium alloys for aircraft engine company exports worth more than $ two 丨 B. It is worth noting that the actuator cylinder engine afterburner ashamed TC6 alloy by using isothermal forging of thin-walled hollow forgings, is the earliest use of aero engine isothermal forging of large bearing parts for our titanium alloys in aircraft engines application accumulated practical experience. The machine has developed five types of engines, using nine grades of titanium seamless pipe, titanium alloys used in China is currently the most burning aircraft. From the use of titanium level analysis, TCll (BT9), ZT3 is heat resistant alloy 500 long-term use of it, up to the international level in the early 1980s. From the engine with titanium content 'points off, Titanium Pan zero weight of the total weight accounted for 14% of the engine, the engine is a single titanium quotas were 855kg and 1055kg, is China's current production of aviation engines loquat amount up to the amount of titanium models .

2014年12月17日星期三

CASIC titanium tube bending mold development Breakthrough

May 13 from the China Aerospace Science and Industry Corporation Second Hospital informed that the hospital's 699 factory independently developed titanium tube bending mold tryout before success, marking the plant of large diameter, thin-walled titanium tube bending mold breakthrough research. CNMn. The study was to fill the gaps in the development of high-precision bending mold.

CNMn.

According to reports, the proposed design requirements by NPU large diameter thin-walled titanium tube bending mold, are set heating, water cooling, heat in one of the bending mold. CNMn. Due to operating temperature, materials, cooling and temperature transfer, etc., prone to wrinkling, cracking and other defects, there is no domestic manufacturers can do this kind of mold design and processing. CNMn. 699 plant to take a variety of processing, cooling, fully consider the impact of the process of bending mold thermal expansion and contraction of the mold, and ultimately succeeded in developing such a large-diameter thin-walled titanium flat bar tube bending mold. CNMn. Allegedly, this technology represents the highest level of domestic bending technology.

699 Factory is one of the earliest manufacturers involved bending die, a set design, processing of mature technologies, design and manufacture a variety of over-bender die abroad, mainly used in aviation, aerospace, motorcycle and automobile exhaust, pipe bending hydraulic system.

2014年12月14日星期日

Titanium History

Concept definition: titanium-based alloy is added to other elements of the alloy known as titanium. Titanium has a low density, high strength, corrosion resistance, good process performance, etc., is an ideal material for aerospace engineering structures.

Scope of the study: the structure of titanium and titanium alloys can be divided into heat resistant titanium, titanium alloy or α, β-type titanium alloys and α + β type titanium alloy. Scope of the study also includes forming technology of titanium alloys, powder metallurgy technology, rapid solidification technology, titanium and other military and civilian.

(A) the development process

In the early 1950s - early 1970s

Demand for power: To meet the needs of the aviation industry for materials, titanium and attention to the development of technology based primarily on metallurgy and technology.

Main features: This phase is characterized by the gradual shift from exploration and research applications of the material. The main materials are Ti-6Al-4V, Ti-5Al-2.5Sn, mainly for aircraft engines, space pressure vessel, such as the engine casing.

Typical results and products: Typical materials: Ti-6Al-4V, Ti-5Al-2.5Sn

70 years to 90 years

Demand for power: to expand the application fields of titanium welding wire, titanium industry has been developing rapidly, new technology and new technology to promote the development of titanium forming process.

Main features: This stage is characterized by: (1) titanium increasing amount of applications in the aerospace industry and in other industries such as marine engineering, chemical, electric power, metallurgy, medical, and other applications are increasing, becoming the third metal. (2) new titanium continue to come out, such as high-strength titanium alloys, heat-resistant titanium alloy. (3) the use of new technology such as super plastic forming, rapid solidification technology and isothermal forging. (4) To expand the application emphasis on reducing costs.

Typical results and products: Typical materials: Ti-1100, Ti-1023, IMI834, Timetal62S, SP-700, etc.

(B) the current level and development trend

Titanium is used widely in the aerospace industry of a metal material, use can be divided into structural titanium and high temperature titanium alloy (use temperature> 400 ℃).

Titanium alloy Ti-6Al-4V to representatives, the alloy has been widely used on aircraft, missiles, and by the time the main load-bearing structural components turn structure. To accommodate the higher strength and toughness requirements (such as strength increased to 1275 ~ 1373MPa, strength increased to 29 ~ 33, the elastic modulus increased to 196GPa), developed in recent years, many new titanium alloy, such as the United States, Ti-15V-3Cr -3Sn-3Al; Ti-3Al-8V-6Cr-4Mo-4Zr (β-C), Ti-6Al-2Sn-2Zr-2Cr-2Mo-0.23Si, Ti-4.5Al-1.5Cr; British Ti-4Al -4Mo-2Sn-0.5Si (IMI500), Japan SPF00, CR800, SP700 and the former Soviet Union and other BT22. Where Ti-15-333 casting and β-C can be replaced precipitation hardening stainless steel and nickel-based alloys, Ti-6-22-22 in the United States Advanced Tactical Fighter (ATF) prototype F-22A in the accounts for 22% (by weight) . Japan's SP700 (Ti-4.5Al-3V-2Mo-2Fe), only high strength, and superplasticity at up to 755 ℃, elongation up to 2000%, good formability, low cost, can replace Ti-6Al-4V has been used in aerospace components.

High temperature titanium alloy made some progress in recent years in the field, the United States and Britain dominate. But the two methods used to develop and focus is different. The United Kingdom is the α-phase solid solution strengthening the necessary means for improving the creep strength without β phase coexistence approach, focusing on the study of nearly α type alloys, namely the development in order to improve the creep strength based Ti-4Al-2Sn- 4Mo-0.5Si (using temperature 400 ℃), Ti-11Sn-2.25Al-5Zr-1Mo-0.2Si (IMI679, use temperature 450 ℃), Ti-6Al-5Zr-0.5Mo-0.25Si (IMI685) alloys and to improve the fatigue strength based Ti-5.5Al-3.5Sn-3Zr-1Nb-0.3Mo-0.3Si (IMI829) and Ti-5.5Al-4.5Sn-4Zr-0.4Mo-0.8Nb-0.4Si (IMI834).

The United States is used to improve the fatigue strength at the expense of the creep strength of the method, focusing on high molybdenum content of the alloy studied, such as Ti-6Al-2Sn-4Zr-2Mo (6242, operating temperature 470 ℃), 6242S (using temperature 500 ℃) alloys. Subsequently, the research and development of the Ti-6Al-2.7Sn-4Zr-0.4Mo-0.45Si alloy (Ti-1100), which uses the temperature increased to 600 ℃.

Recently, the US has developed a Timetal21S (Ti-15Mo-2.7Nb-3Al-0.2Si) (also known as β21S), the use of temperature 704 ℃, the catheter can be used in the manufacture of high temperature and pressure pipes, are preferable for the US National Space Plane (NASP) metal matrix composite body with the matrix material. Currently, these new high-temperature titanium alloys are not yet entered the practical stage.

At present, high-strength titanium alloy superplastic forming technology has developed rapidly, the trend is forming isothermal forging pressure and vacuum forming.

The United States in the development and application of titanium wire manufacturers alloy, has been in the lead, according to statistics in the US aviation industry, titanium consumption ratio of 70%, the United States in terms of forming titanium alloy, the main use of isothermal forging superplastic conditions and sheet metal forming. To reduce costs, expand the application, the United States launched a new alloy grades, such as Timetal62S (Ti-6Al-2Fe-0.1Si), vanadium and iron in the cost of generation is better than Ti-6Al-V, and the performance is comparable.

Titanium industry over the former Soviet Union has 35 years of history, its development process smooth, no big ups and downs. Production of a large number of the Ti-6Al-4V and Ti-5Al-2.5Sn similar series of high-temperature high-strength alloy and alloy, and studied the special corrosion resistant alloys, such as 4200,4210,4207 and so on, in the aerospace industry, the former widely used in the Soviet Union under atmospheric pressure conditions Pedal Titanium Axle superplastic forming process.

Britain in research and application of heat resistant titanium alloys with the United States each aspect advantage, but its emphasis on research in recent α type alloys, namely to increase the creep strength and vigorously develop focused alloys such as Ti-4Al-2Sn-4Mo-0.5Si , Ti-11Sn-2.25Al-5Zr-1Mo-0.2Si (IMI879), Ti-6Al-5Zr-0.5Mo-0.25Si (IMI685), among IMI685 has been widely used in Europe.

In recent years, the Japanese in the study of titanium has also made great progress, such as to reduce the cost of developing the SP-700 (Ti-4.5Al-3V-2Mo-2Fe) alloy, forming properties of the alloy than Ti-6Al -4V. Japan's low strain rate superplasticity vacuum forming process.

Scope of the study: the structure of titanium and titanium alloys can be divided into heat resistant titanium, titanium alloy or α, β-type titanium alloys and α + β type titanium alloy. Scope of the study also includes forming technology of titanium alloys, powder metallurgy technology, rapid solidification technology, titanium and other military and civilian.

(A) the development process

In the early 1950s - early 1970s

Demand for power: To meet the needs of the aviation industry for materials, titanium and attention to the development of technology based primarily on metallurgy and technology.

Main features: This phase is characterized by the gradual shift from exploration and research applications of the material. The main materials are Ti-6Al-4V, Ti-5Al-2.5Sn, mainly for aircraft engines, space pressure vessel, such as the engine casing.

Typical results and products: Typical materials: Ti-6Al-4V, Ti-5Al-2.5Sn

70 years to 90 years

Demand for power: to expand the application fields of titanium welding wire, titanium industry has been developing rapidly, new technology and new technology to promote the development of titanium forming process.

Main features: This stage is characterized by: (1) titanium increasing amount of applications in the aerospace industry and in other industries such as marine engineering, chemical, electric power, metallurgy, medical, and other applications are increasing, becoming the third metal. (2) new titanium continue to come out, such as high-strength titanium alloys, heat-resistant titanium alloy. (3) the use of new technology such as super plastic forming, rapid solidification technology and isothermal forging. (4) To expand the application emphasis on reducing costs.

Typical results and products: Typical materials: Ti-1100, Ti-1023, IMI834, Timetal62S, SP-700, etc.

(B) the current level and development trend

Titanium is used widely in the aerospace industry of a metal material, use can be divided into structural titanium and high temperature titanium alloy (use temperature> 400 ℃).

Titanium alloy Ti-6Al-4V to representatives, the alloy has been widely used on aircraft, missiles, and by the time the main load-bearing structural components turn structure. To accommodate the higher strength and toughness requirements (such as strength increased to 1275 ~ 1373MPa, strength increased to 29 ~ 33, the elastic modulus increased to 196GPa), developed in recent years, many new titanium alloy, such as the United States, Ti-15V-3Cr -3Sn-3Al; Ti-3Al-8V-6Cr-4Mo-4Zr (β-C), Ti-6Al-2Sn-2Zr-2Cr-2Mo-0.23Si, Ti-4.5Al-1.5Cr; British Ti-4Al -4Mo-2Sn-0.5Si (IMI500), Japan SPF00, CR800, SP700 and the former Soviet Union and other BT22. Where Ti-15-333 casting and β-C can be replaced precipitation hardening stainless steel and nickel-based alloys, Ti-6-22-22 in the United States Advanced Tactical Fighter (ATF) prototype F-22A in the accounts for 22% (by weight) . Japan's SP700 (Ti-4.5Al-3V-2Mo-2Fe), only high strength, and superplasticity at up to 755 ℃, elongation up to 2000%, good formability, low cost, can replace Ti-6Al-4V has been used in aerospace components.

High temperature titanium alloy made some progress in recent years in the field, the United States and Britain dominate. But the two methods used to develop and focus is different. The United Kingdom is the α-phase solid solution strengthening the necessary means for improving the creep strength without β phase coexistence approach, focusing on the study of nearly α type alloys, namely the development in order to improve the creep strength based Ti-4Al-2Sn- 4Mo-0.5Si (using temperature 400 ℃), Ti-11Sn-2.25Al-5Zr-1Mo-0.2Si (IMI679, use temperature 450 ℃), Ti-6Al-5Zr-0.5Mo-0.25Si (IMI685) alloys and to improve the fatigue strength based Ti-5.5Al-3.5Sn-3Zr-1Nb-0.3Mo-0.3Si (IMI829) and Ti-5.5Al-4.5Sn-4Zr-0.4Mo-0.8Nb-0.4Si (IMI834).

The United States is used to improve the fatigue strength at the expense of the creep strength of the method, focusing on high molybdenum content of the alloy studied, such as Ti-6Al-2Sn-4Zr-2Mo (6242, operating temperature 470 ℃), 6242S (using temperature 500 ℃) alloys. Subsequently, the research and development of the Ti-6Al-2.7Sn-4Zr-0.4Mo-0.45Si alloy (Ti-1100), which uses the temperature increased to 600 ℃.

Recently, the US has developed a Timetal21S (Ti-15Mo-2.7Nb-3Al-0.2Si) (also known as β21S), the use of temperature 704 ℃, the catheter can be used in the manufacture of high temperature and pressure pipes, are preferable for the US National Space Plane (NASP) metal matrix composite body with the matrix material. Currently, these new high-temperature titanium alloys are not yet entered the practical stage.

At present, high-strength titanium alloy superplastic forming technology has developed rapidly, the trend is forming isothermal forging pressure and vacuum forming.

The United States in the development and application of titanium wire manufacturers alloy, has been in the lead, according to statistics in the US aviation industry, titanium consumption ratio of 70%, the United States in terms of forming titanium alloy, the main use of isothermal forging superplastic conditions and sheet metal forming. To reduce costs, expand the application, the United States launched a new alloy grades, such as Timetal62S (Ti-6Al-2Fe-0.1Si), vanadium and iron in the cost of generation is better than Ti-6Al-V, and the performance is comparable.

Titanium industry over the former Soviet Union has 35 years of history, its development process smooth, no big ups and downs. Production of a large number of the Ti-6Al-4V and Ti-5Al-2.5Sn similar series of high-temperature high-strength alloy and alloy, and studied the special corrosion resistant alloys, such as 4200,4210,4207 and so on, in the aerospace industry, the former widely used in the Soviet Union under atmospheric pressure conditions Pedal Titanium Axle superplastic forming process.

Britain in research and application of heat resistant titanium alloys with the United States each aspect advantage, but its emphasis on research in recent α type alloys, namely to increase the creep strength and vigorously develop focused alloys such as Ti-4Al-2Sn-4Mo-0.5Si , Ti-11Sn-2.25Al-5Zr-1Mo-0.2Si (IMI879), Ti-6Al-5Zr-0.5Mo-0.25Si (IMI685), among IMI685 has been widely used in Europe.

In recent years, the Japanese in the study of titanium has also made great progress, such as to reduce the cost of developing the SP-700 (Ti-4.5Al-3V-2Mo-2Fe) alloy, forming properties of the alloy than Ti-6Al -4V. Japan's low strain rate superplasticity vacuum forming process.

2014年12月9日星期二

Titanium and titanium alloy material is one of the most promising metal in the 21st century's

Titanium is a refractory metal of a light metal, a density of 4.5 g / cm3, 57% only of iron. Strength titanium alloy with high strength comparable to steel, but also has good heat resistance and low temperature performance, long-term work at certain alloy between 450 ℃ ~ 550 ℃ and minus 250 ℃. Titanium has good salt tolerance classes, the ability to seawater and nitric acid corrosion, Ti-30M alloy is resistant to high concentrations of hydrochloric acid and sulfuric acid corrosion. These advantages of titanium, titanium deserved to be called a "space" metal, "Ocean" and the following metal steel, aluminum metal after the third and so on.

Titanium is very versatile, as the "space" of metal, titanium standard parts is used as aircraft, rocket engine materials, structural materials, such as skin and various pipe joints. A Boeing 747 aircraft with 42.7 tons of titanium, titanium 57 t 777, 777ER aircraft titanium even up to 68 tons, F-15 fighter jets also up 24.5 tons of titanium. The United States in the 21st century superiority fighter F-22 is the only large-scale use of titanium ensures excellent its various properties.

As a "sea" of metal, titanium is currently able to mass-produced, the lowest price, and almost entirely free from metal sea erosion. Extensive use of the former Soviet nuclear submarine manufacturing titanium shell, the 3680-ton Alpha submarines, each ship 560 tons of titanium, medical titanium alloy Typhoon-class missile submarines 9000 tons. After using these submarines Titanium has a non-magnetic, dive deep (up to 900 m), fast speed, low noise and less maintenance times and so on. Titanium is also used extensively for offshore oil open using pipelines, nuclear power plants and fire station in the condenser. In the 21st century, the development of new marine industry, titanium spring wire is bound to play a major role in safeguarding.

Titanium used in the petrochemical industry, but has a pivotal role. Titanium and titanium alloys are widely used to produce acetaldehyde production process and the heat exchange reactor, the urea synthesis column production, wet chlorine gas cooler, chlor-alkali and chlorate electrolysis electrode, the production of ammonia soda ash cooling towers, nitrate Production of heat exchangers, reactors and distillation column. Titanium and its alloys in these areas are irreplaceable.

The company aims: to capture the market with advanced technology to market quality product satisfaction to win the contract and credit market, the quality of the first single to shine. The company dedicated to customer service at home and abroad, warmly welcome to visit our friends. Choose our products will bring you the desired economic benefits!

Titanium is very versatile, as the "space" of metal, titanium standard parts is used as aircraft, rocket engine materials, structural materials, such as skin and various pipe joints. A Boeing 747 aircraft with 42.7 tons of titanium, titanium 57 t 777, 777ER aircraft titanium even up to 68 tons, F-15 fighter jets also up 24.5 tons of titanium. The United States in the 21st century superiority fighter F-22 is the only large-scale use of titanium ensures excellent its various properties.

As a "sea" of metal, titanium is currently able to mass-produced, the lowest price, and almost entirely free from metal sea erosion. Extensive use of the former Soviet nuclear submarine manufacturing titanium shell, the 3680-ton Alpha submarines, each ship 560 tons of titanium, medical titanium alloy Typhoon-class missile submarines 9000 tons. After using these submarines Titanium has a non-magnetic, dive deep (up to 900 m), fast speed, low noise and less maintenance times and so on. Titanium is also used extensively for offshore oil open using pipelines, nuclear power plants and fire station in the condenser. In the 21st century, the development of new marine industry, titanium spring wire is bound to play a major role in safeguarding.

Titanium used in the petrochemical industry, but has a pivotal role. Titanium and titanium alloys are widely used to produce acetaldehyde production process and the heat exchange reactor, the urea synthesis column production, wet chlorine gas cooler, chlor-alkali and chlorate electrolysis electrode, the production of ammonia soda ash cooling towers, nitrate Production of heat exchangers, reactors and distillation column. Titanium and its alloys in these areas are irreplaceable.

The company aims: to capture the market with advanced technology to market quality product satisfaction to win the contract and credit market, the quality of the first single to shine. The company dedicated to customer service at home and abroad, warmly welcome to visit our friends. Choose our products will bring you the desired economic benefits!

2014年12月5日星期五

Titanium wire

Titanium titanium wire deposit before storing nuclear waste in the role, you should first introduce high-level waste packaging system.titanium foil for sale Such systems can be summarized as a deep, at the bottom or depot level roadway tunnel in this deep, Ann stood a tank long 3m, 0.6m diameter of about 0.3 is equipped with a high-level radioactive waste metal cans. These tunnels below ground at 600 a 1000m.

First,seamless titanium tube the role should be clearly packaged as part of the waste cans and packaging waste layer.

Low titanium wire due to corrosion and high temperature corrosion and pitting of performance gaps, and therefore accounted for advantage in the selection of the outer layer of packaging material. Analysis showed that, compared with the relatively inexpensive iron-based alloys and nickel-based alloys, by unit volume weight, titanium wire as the outer packaging material aid cost-effective.

2014年12月2日星期二

Application of titanium in the chemical industry

Titanium used in petroleum, chemical and other sectors

Petrochemical reactors, pressure vessels, heat exchangers, separators, piping, distillation tower condenser lining and so on.

Chemical industry distillation columns, reactors, pressure vessels, heat exchangers, filters, measuring instruments, turbine blades, pumps, valves, pipes, chlor-alkali production electrodes, synthetic lining tower, other acid-resistant equipment lining.

Paper Industry blender, bleaching tower, heating bath, the reaction tower piping.

Bleacher continuous textile industry, a distillation column, the reaction vessel, a condenser, heat exchange tubes, centrifuge, spinneret, valves, pumps.

Metallurgical Industry steel getter alloy additives, superconducting alloy material, electrolytic high purity metal (e.g., sodium, nickel, cobalt) of the cathode plate and the plating bath and the like.

Desalination and power plant heat exchangers, condensers, water heaters, pipes, other contact with seawater equipment.

Naval vessels housing industry, decks, valves, wing, propeller boats, drive shaft, the steam engine, the deep submarine pressure tanks, development of marine equipment.

Other titanium industrial bar ultrahigh vacuum pumps, medical and orthopedic instruments, artificial joints, pharmaceutical and food industry equipment.

Second, the titanium in the aviation industry application specific strength of titanium and its alloys (important than strength) is high in the metal structure of the material, its strength steel equivalent, but its importance is only 57% of the steel. In addition, the heat resistance of titanium and its alloys are strong, in the atmosphere of 500 ℃ can still maintain good strength and stability, but also short-term operating temperature even higher. The aluminum 150 ℃, stainless steel at 310 ℃ to lose their mechanical properties. When the aircraft missiles, rocket-speed flight, the engine and the surface temperature is very high, aluminum was not competent, the application of titanium alloy is very appropriate. It is because when the titanium and its alloys have high strength, light weight, heat and strong overall excellent performance, aircraft used instead of other metals in it, not only to extend the service life of the aircraft, but also can reduce their weight, thus greatly improve its flight performance. Therefore, titanium is one of the aviation industry and the aerospace industry's most promising structural materials. Titanium and its alloys. Mach 2 aircraft that its engine with titanium increased, but also part of the body needs titanium. Greater than Mach 3.5 aircraft, the engine inlet temperature is very high, it is not a high impact strength, can withstand high pressure, anti-vibration. Therefore, titanium round bar and its alloys in rockets, missiles and spacecraft only for the manufacture of the engine casing and structural components, and for the manufacture of pressure vessels, such as high-pressure gas cylinders, cryogenic liquid fuel tanks. In addition, titanium and its alloys in nuclear reactors and weapons have military applications.

Petrochemical reactors, pressure vessels, heat exchangers, separators, piping, distillation tower condenser lining and so on.

Chemical industry distillation columns, reactors, pressure vessels, heat exchangers, filters, measuring instruments, turbine blades, pumps, valves, pipes, chlor-alkali production electrodes, synthetic lining tower, other acid-resistant equipment lining.

Paper Industry blender, bleaching tower, heating bath, the reaction tower piping.

Bleacher continuous textile industry, a distillation column, the reaction vessel, a condenser, heat exchange tubes, centrifuge, spinneret, valves, pumps.

Metallurgical Industry steel getter alloy additives, superconducting alloy material, electrolytic high purity metal (e.g., sodium, nickel, cobalt) of the cathode plate and the plating bath and the like.

Desalination and power plant heat exchangers, condensers, water heaters, pipes, other contact with seawater equipment.

Naval vessels housing industry, decks, valves, wing, propeller boats, drive shaft, the steam engine, the deep submarine pressure tanks, development of marine equipment.

Other titanium industrial bar ultrahigh vacuum pumps, medical and orthopedic instruments, artificial joints, pharmaceutical and food industry equipment.

Second, the titanium in the aviation industry application specific strength of titanium and its alloys (important than strength) is high in the metal structure of the material, its strength steel equivalent, but its importance is only 57% of the steel. In addition, the heat resistance of titanium and its alloys are strong, in the atmosphere of 500 ℃ can still maintain good strength and stability, but also short-term operating temperature even higher. The aluminum 150 ℃, stainless steel at 310 ℃ to lose their mechanical properties. When the aircraft missiles, rocket-speed flight, the engine and the surface temperature is very high, aluminum was not competent, the application of titanium alloy is very appropriate. It is because when the titanium and its alloys have high strength, light weight, heat and strong overall excellent performance, aircraft used instead of other metals in it, not only to extend the service life of the aircraft, but also can reduce their weight, thus greatly improve its flight performance. Therefore, titanium is one of the aviation industry and the aerospace industry's most promising structural materials. Titanium and its alloys. Mach 2 aircraft that its engine with titanium increased, but also part of the body needs titanium. Greater than Mach 3.5 aircraft, the engine inlet temperature is very high, it is not a high impact strength, can withstand high pressure, anti-vibration. Therefore, titanium round bar and its alloys in rockets, missiles and spacecraft only for the manufacture of the engine casing and structural components, and for the manufacture of pressure vessels, such as high-pressure gas cylinders, cryogenic liquid fuel tanks. In addition, titanium and its alloys in nuclear reactors and weapons have military applications.

2014年10月26日星期日

titanium standard parts to maintain steady growth in all areas of the application will

Until now, the growth of titanium standard applied in non-aeronautical, aerospace sector is still relatively stable.titanium grade 2 sheet If this trend is maintained, it will lay the foundation for the titanium standard parts industry, and to reduce the impact that is difficult to predict market demand for that part of the passive,Titanium tube supplier but in the future there is also a very unstable situation that may arise due to the titanium standard price increases, which in the chemical industry and the status of the application of the heat exchanger will not be compromised? titanium standard parts in energy production, conversion and storage, or in a new land transport and marine equipment, etc. will develop new and important purpose? titanium plates In these areas of instability will not be home in aviation, aerospace applications that impact?

Because titanium standard parts Pat widely used in various aspects, even if these conditions, due to different causes, but also by the cycle is different, so the overall effect is not considered. With titanium standard parts continue to expand to new energy and industry,titanium wire manufacturers making it possible to make titanium standard parts industry remains substantially stable growth rate, and will stimulate more investment, more research conducted disaster and infrastructure development.

Because titanium standard parts Pat widely used in various aspects, even if these conditions, due to different causes, but also by the cycle is different, so the overall effect is not considered. With titanium standard parts continue to expand to new energy and industry,titanium wire manufacturers making it possible to make titanium standard parts industry remains substantially stable growth rate, and will stimulate more investment, more research conducted disaster and infrastructure development.

2014年10月25日星期六

Titanium standard parts feature

Titanium standard parts is a chemical element, is a silvery-white transition metal.

Titanium standard parts is characterized by light weight, high strength, with a metallic luster, have a good corrosion resistance.

Titanium standard parts, good high temperature, titanium grade 2 sheet low temperature resistance, anti-acid, anti-alkali and high-strength, low density.

Titanium standard parts is characterized by light weight, high strength, with a metallic luster, have a good corrosion resistance.

Titanium standard parts, good high temperature, titanium grade 2 sheet low temperature resistance, anti-acid, anti-alkali and high-strength, low density.

titanium is a very active metal, and its equilibrium potential is low, the corrosion tendency of the thermodynamic medium is large. But in fact a number of titanium is stable medium, such as titanium in an oxidizing, neutral or weakly reducing medium such as corrosion resistant. This is because there are a lot of titanium and oxygen affinity,titanium whole distributor in the air or oxygen-containing medium, the titanium surface layer of dense, strong adhesion, large inert oxide film to protect the titanium substrate from corrosion. Even due to mechanical wear and tear will soon heal or regenerate. This indicates that the passivation of titanium is a metal having a strong tendency.

2014年10月19日星期日

titanium bars how to clean the filter

According to the different nature of pharmaceutical production requirements solvents and media technology engineering company for titanium filter regeneration procedures are as follows:

1, caustic: 3-5% solution of sodium hydroxide AR soak 30-60 minutes or so a temperature of 40 degrees.titanium alloy sheet Best in ultrasonic cleaning machine. After soaking with deionized water or filtered water for injection and outside the red to neutral, measured conductivity. Dry with clean air ≥0.4Mpa pressure.

2, acid: 5% nitric acid solution soak for 8 hours at a temperature of 40 degrees. Best in ultrasonic cleaning machine. After soaking with deionized water or filtered water for injection and outside the red to neutral, measured conductivity.Medical titanium alloy Dry with clean air ≥0.4Mpa pressure.

3, the above two methods may be used alone may also be used interchangeably with each other. If the conditions can be combined with ultrasonic cleaning machine best.

4, organic pollution can be combined with a surfactant cleaning, cell debris contaminated system conjugating enzyme cleaning effect is more ideal. (Food and drink can be a high concentration of citric acid wash)

Note: grade 3 titanium Always online blowback wash (line cleaning with pure liquid or compressed air or clean water filtration recoil) using the above method can reduce the number of cleaning.

1, caustic: 3-5% solution of sodium hydroxide AR soak 30-60 minutes or so a temperature of 40 degrees.titanium alloy sheet Best in ultrasonic cleaning machine. After soaking with deionized water or filtered water for injection and outside the red to neutral, measured conductivity. Dry with clean air ≥0.4Mpa pressure.

2, acid: 5% nitric acid solution soak for 8 hours at a temperature of 40 degrees. Best in ultrasonic cleaning machine. After soaking with deionized water or filtered water for injection and outside the red to neutral, measured conductivity.Medical titanium alloy Dry with clean air ≥0.4Mpa pressure.

3, the above two methods may be used alone may also be used interchangeably with each other. If the conditions can be combined with ultrasonic cleaning machine best.

4, organic pollution can be combined with a surfactant cleaning, cell debris contaminated system conjugating enzyme cleaning effect is more ideal. (Food and drink can be a high concentration of citric acid wash)

Note: grade 3 titanium Always online blowback wash (line cleaning with pure liquid or compressed air or clean water filtration recoil) using the above method can reduce the number of cleaning.

2014年10月10日星期五

titanium standard parts processing methods and uses

titanium standard parts into a variety of applications need to go through processing.titanium bar supplier Titanium standard parts processing methods have cutting, vacuum casting, EDM etching and super plastic forming. Due to the ever-changing form of denture parts and vary, so the vacuum casting is the best current methods. Inlays, crowns and bridges made of, can also use CAD / CAM method, high precision, less time-consuming, is a new technology being studied.

titanium standard parts of the proportion of small, high-strength, corrosion resistance, biocompatibility,titanium wire as the cutting-edge science and technology materials and high functional materials have strong vitality, is an ideal structural materials and corrosion-resistant materials, the military industry and civil all areas of industry, such as has been widely applied.

titanium standard parts of the proportion of small, high-strength, corrosion resistance, biocompatibility,titanium wire as the cutting-edge science and technology materials and high functional materials have strong vitality, is an ideal structural materials and corrosion-resistant materials, the military industry and civil all areas of industry, such as has been widely applied.

2014年9月27日星期六

corrosion resistance of titanium standard parts

titanium is a very active metal, and its equilibrium potential is low, the corrosion tendency of the thermodynamic medium is large. But in fact a number of titanium is stable medium,Medical titanium bar such as titanium in an oxidizing, neutral or weakly reducing medium such as corrosion resistant. This is because there are a lot of titanium and oxygen affinity, in the air or oxygen-containing medium, the titanium surface layer of dense, strong adhesion, large inert oxide film to protect the titanium substrate from corrosion. Even due to mechanical wear and tear will soon heal or regenerate. This indicates that the passivation of titanium is a metal having a strong tendency. Dielectric oxide film of titanium at temperatures below 315 ℃ always maintain this characteristic.

In order to improve the corrosion resistance of titanium, developed oxidation, electroplating, plasma spraying, ion nitriding surface treatment technology, ion implantation and laser processing of titanium oxide film played a role enhanced protection, access to the desired corrosion resistance effect. For sulfuric acid, hydrochloric acid, methyl amine solution,surgical implant titanium the high temperature and high temperature chloride wet chlorine produced in need of metal materials, the development of the titanium - molybdenum, titanium - palladium, titanium - molybdenum - and a series of corrosion resistant nickel titanium alloy. -32 Titanium castings using titanium-molybdenum alloy, often occur on or crevice corrosion pitting environment uses a titanium -0.3 -0.8 partial molybdenum-nickel alloy or titanium equipment -0.2 using titanium-palladium alloy, which have received a very good use effect.

In order to improve the corrosion resistance of titanium, developed oxidation, electroplating, plasma spraying, ion nitriding surface treatment technology, ion implantation and laser processing of titanium oxide film played a role enhanced protection, access to the desired corrosion resistance effect. For sulfuric acid, hydrochloric acid, methyl amine solution,surgical implant titanium the high temperature and high temperature chloride wet chlorine produced in need of metal materials, the development of the titanium - molybdenum, titanium - palladium, titanium - molybdenum - and a series of corrosion resistant nickel titanium alloy. -32 Titanium castings using titanium-molybdenum alloy, often occur on or crevice corrosion pitting environment uses a titanium -0.3 -0.8 partial molybdenum-nickel alloy or titanium equipment -0.2 using titanium-palladium alloy, which have received a very good use effect.

2014年9月25日星期四

Why titanium bars so popular filter

The main reason titanium bars cartridge is sought after by the majority of users it contains four major advantages.

1 will not be accepted corrosion in steam filter when melted.

2.titanium bars draw filter structure,titanium material penetration ability, low resistance.

3 is more than five times the normal service life of the filter.

4. shape diversification,Titanium bars can facilitate the production of various shapes titanium rod filter.

1 will not be accepted corrosion in steam filter when melted.

2.titanium bars draw filter structure,titanium material penetration ability, low resistance.

3 is more than five times the normal service life of the filter.

4. shape diversification,Titanium bars can facilitate the production of various shapes titanium rod filter.

2014年9月20日星期六

Titanium standard parts feature

Titanium standard parts of the two properties are most useful, corrosion resistance,titanium material and metal in the highest strength - weight ratio. In the non-alloyed state, the strength of Titanium standard parts are similar with some steel, but 45% lighter. There are two allotropes and five natural isotopes from Ti to Ti, which is the highest abundance of Ti (73.8%). The Titanium standard parts physical properties and chemical properties of zirconium and titanium are similar,medical titanium plate this is because the same number of valence electrons of the two, and belong to the same family in the periodic table.

2014年9月18日星期四

titanium bars filters Cautions

1 collision to avoid scratches, dust and oil.

2 in use,titanium wire its working pressure should not exceed the rated working pressure.

3 When three normal use, at least 3-5 minutes of low-voltage start-up time, the relative pressure should be controlled below 0.5Mpa, and then gradually transferred to the normal operating pressure of work needed (not to exceed the maximum pressure 0.4Mpa).

4 titanium bars after work to run to a certain period, probably due to clogged filter elements,titanium manufacturer resulting in increased pressure to reduce the flow, you need to recoil or backwash regeneration. Depending on the regeneration cycle the rated pressure and flow rate setting.

2 in use,titanium wire its working pressure should not exceed the rated working pressure.

3 When three normal use, at least 3-5 minutes of low-voltage start-up time, the relative pressure should be controlled below 0.5Mpa, and then gradually transferred to the normal operating pressure of work needed (not to exceed the maximum pressure 0.4Mpa).

4 titanium bars after work to run to a certain period, probably due to clogged filter elements,titanium manufacturer resulting in increased pressure to reduce the flow, you need to recoil or backwash regeneration. Depending on the regeneration cycle the rated pressure and flow rate setting.

2014年9月12日星期五

titanium bars precision filter characteristics

titanium bars precision filter no particle shedding,titanium bar stock do not pollute the liquid, in line with food hygiene and pharmaceutical GMP requirements. High temperature (300 ℃ wet), acid corrosion, oxidation resistance, suitable for a variety of environments. titanium bars precision filter pressure low, small footprint, flow rate, 0.2 MPa up to maximum flow. Good mechanical properties of titanium bars precision filter can filter press may filtration,baoji titanium industry simple operation. (Reverse-free residue removing carbon filter, heat filter).

2014年9月1日星期一

hailed myth transit and ground son buy titanium bar

Titanium element symbol Ti, hailed myth transit and ground son.

Despite all walks of life now have titanium figure, but titanium is still in people's minds very strange, as is well known , unlike iron, aluminum, household name . Therefore, understanding titanium, titanium awareness , attention titanium buy titanium sheet becomes more urgent. Despite the early eighties of the last century , the state established the National Leading Group Office to promote the application of titanium , 20 years, titanium industry has been rapid development , further widening the use of titanium , titanium but in the end what that is, how to use, more its still know these people I do not know why.

A lot of people did not know what titanium , titanium past two years but the market is the same as the name "Titanium " hot, too hot for some people who do not understand the titanium -row actually said the words , that is, people say open yellow cavity. seamless titanium pipe After more complicated after the titanium smelting process out , the shape of the sponge -like, it is called titanium sponge . Since last year, the market is extremely strong titanium sponge , the price soared from 5,6 million ton a ton to more than 20 million , the highest it has sold more than 30 million yuan a ton , it is no exaggeration to say that now in the hands of owners who titanium sponge whoever has the opportunity to make a fortune. In this hot market , some knowledge of the money and did not know who to care between acquaintances to buy titanium sponge titanium, titanium openings actually say do not buy just to buy a sponge , jokes jokes Yeah , even the product names are confused on buying titanium sponge , indeed ironic . Jokes apart , there are also thinking of a joke . How to make titanium into the homes of ordinary people , to let people know that just as iron titanium , aluminum, titanium promote the application of this work is to be valued . I want to let more people know about titanium, titanium know , titanium standards the use of titanium , titanium had to start from the origin , and the depth into the room , go slowly so that people know the truth about titanium .

2014年8月29日星期五

He was a very strong interest and research titanium bars for sale

In 1789, the British discoverer of titanium analytical chemist Glenn Gore . Once, he conducted research on the UK Manasseh Chen valley produced a black magnetic ore, found to contain brown slag powder. He was a very strong interest and research. molybdenum sheet Did not arouse people's attention. 1795 , German mineralogist and analytical chemist Klaproth in the analysis region of Hungary Bowie Nick red rutile production , Chen found mine looks like Manasseh , after comparative studies, knows the difference between the main ingredient similar, but Manasseh Chen ore containing iron . Klaproth convinced that this is a new metal oxide , and curiously named the new element to this "Titanium" ( Ti ) , the name refers to a Greek myth : that heaven and earth son called first generation "Too Dan Adams " (Titans), it is the legendary Titan , from , Ti titanium has become a symbol . 1849 German chemist Weiler with potassium and fluorine potassium titanate of heat , a system of impure metal titanium. Smelting titanium is present , first through a series of titanium ore processed into titanium tetrachloride, and then titanium bar for sale magnesium or sodium reduction in an inert gas to produce spongy titanium is titanium sponge .

Titan god Titanic. German mineralogist Klaproth in the Greek mythology, the Titans gave reputation "Titanium " is , I'm afraid there was no thought of as titanium and Titan will be the Titanic , and even many of the potential of titanium , it is smart Titans God can not.

In 1986 , when the Chinese Academy of Engineering, Science and Technology Advisor Li Dongying was shot , " the rise of the third metal - titanium" won the Sixth China Golden Rooster Award for best popular science since the son of heaven and earth , " titanium" Tan God has begun in China from strangers into people 's vision . When the " Shenzhou V " manned spacecraft was successfully launched , " titanium" Tan God and the " seamless titanium pipe Shenzhou V " of Xiang blue sky.

Titanium , the son of heaven and earth , and its potential, intelligence will expose grace in different areas in the metal world of the twenty -first century , the number of romantic material also see the metal titanium.

2014年8月26日星期二

the stretch of a spring titanium flat bar

Container of cold water in the aquarium , the stretch of a spring , when the spring into the hot water , springs and automatically folded up . Cold water in the spring to restore its original state , while in hot water , it will shrink , molybdenum sheet spring can be an unlimited number of stretching and shrinking , shrinking again opened. The memory consists of an intelligent made of metal , the microstructure of which has two relatively stable at high temperatures of the alloy can be turned into any shape you want, the alloy at lower temperatures can be stretched , but if it is reheated , it will remember its original shape , and change back. This material is called memory metal (memory metal). It is mainly a nickel titanium material. For example , a helical superalloy, after high temperature annealing , titanium bar for sale which is in the shape of a spiral state. At room temperature , that is forced to use a lot of effort to straighten it , but as long as it is heated to a certain " abnormal temperature ," which seemed to root alloy remembered something, now restored to its original helical shape . How is this going ? Did alloy also has a kind of human memory ? Original not the case ! It's just the use of certain alloys law changes the crystal structure in the solid state with temperature only. For example , a nickel - titanium alloy titanium standards 40oC 40oC above and below the crystal structure is different, but the temperature change in the vertical 40oC , will be contracted or expanded metal , such that its shape is changed .

2014年8月23日星期六

Titanium is a new structural material titanium sheet

Titanium is a new structural material, it has excellent performance , such as low density (~ 4.5g · cm-3), high specific strength and fracture toughness, fatigue strength and resistance to crack propagation ability, hin titanium sheet good low-temperature toughness, excellent corrosion resistance , the maximum operating temperature titanium alloy for some 550 º C, is expected to reach 700 º C. So it gets in the aviation, aerospace, chemical, shipbuilding and other industrial sectors increasingly widely used , is developing rapidly . (Σ0.2 / density ) vs. Temperature light alloys, such as steel , stronger than titanium than other light metals , steel and nickel alloys , and this advantage can be maintained to about 500 º C , so some titanium alloys suitable for manufacturing gas turbine components . titanium wire Approximately 80 percent titanium production for the aviation and aerospace industries. Airframe structural materials such as the U.S. B-1 bomber , the titanium about 21 %, mainly used in the manufacture of the fuselage , wings, skin and bearing components . Airframe structural materials F-15 fighter , the titanium with a capacity of 7000kg, accounting for about 34% of structural weight . Boeing 757 aircraft structural parts , titanium about 5% , with a capacity of 3640kg. McDonnell Douglas (Mc-Donnell-Dounlas) produced DC10 aircraft , titanium with a capacity of 5500kg, accounting for more than 10% of the weight of the structure . The amount of titanium in the chemical and general engineering areas: U.S. , about 15 % of its production in Europe accounts for about 40%. As the excellent corrosion resistance of titanium and its alloys , good mechanical properties , as well as qualified histocompatibility titanium rods make it for the production of biological materials prosthetic devices.

2014年8月21日星期四

Strength titanium and titanium titanium bar stock

Strength titanium and titanium which is relatively large ? Lighter ?

Data showed that: Titanium is used to make parts of the space shuttle . Titanium specific do not know. But there is one thing to do four frames with titanium ------ boxes billboard is fixed with titanium material packaging ! There are also white with yellow . Very shiny very nice ! In fact, the film is outside the iron plating layer "Titanium ." And our mouth as household tap water , hin titanium sheet plating a layer of plastic pipe outside light , indicating that the opinion is stainless steel .

Generally speaking

Plating rack

Is to use titanium rather than using titanium

Titanium is a metal belonging to the strength characteristics

And no corrosion properties of pure titanium

Other

Anode hooks titanium rods mostly belong to the elastic clamping

In addition to specifying titanium addition

Also choose a flexible titanium

Hook of anode materials currently used in

Most Flexible Titanium G4 level of choice

In addition to the material selected

Also affect the ability of the processing again

Robustness and capacity of the current through the welding point

Are decided a rack durability and performance of an important factor

Bad welds

In addition to repeated use breakable outside

Poor conductivity

Is also one of the titanium bar for sale important factors affecting the plating effect

Choose a professional manufacturer in addition to ensure the life of the outside pylons

But also on the quality of your products to ensure the production of

Do not focus on a bargain

Materials Processing indeed correct

You pay

2014年8月20日星期三

Titanium what the benefits of the human buy titanium bar

Titanium what the benefits of the human body

Titanium has a " pro-biotic " ' sex . In the human body , corrosion resistant and non-toxic secretions , have to adapt to any sterilization method . It is widely used in making medical devices, making artificial hip, knee, buy titanium bar shoulder , flank joints, skull , active heart valves , bone clip. When a new packet in the annulus muscle " titanium -bone" , these titanium bone began to maintain the body's normal activities . Titanium is widely distributed in the body , the content of the normal body weight not exceeding 70kg per 15mg, its role is unclear. However, titanium can stimulate phagocytic cells, the immune system has been proven to enhance this role .

Characteristics of titanium itself has not the high hardness and light rust deterioration, resulting in a stable metal or metal allergies .

Titanium has a special current characteristics of the titanium bar for sale human body will produce beneficial physiological effects and its chemical stability, and will not produce the change or deterioration.

Titanium beneficial to humans , and quite safe , very fit body . Because titanium products will buy titanium sheet settle the current body , relieve muscle tension state, therefore, the spirit will get loose , will gradually relax the muscles , and improve athletic performance.

2014年8月12日星期二

Titanium is a new structural material Pedal Titanium Axle

Titanium is a new structural material, it has excellent performance , such as low density (~ 4.5g · cm-3), high specific strength and fracture toughness, fatigue strength and resistance to crack propagation ability, good low-temperature medical grade titanium alloy toughness, excellent corrosion resistance , the maximum operating temperature titanium alloy for some 550 º C, is expected to reach 700 º C. So it gets in the aviation, aerospace, chemical, shipbuilding and other industrial sectors increasingly widely used , is developing rapidly . (Σ0.2 / density ) vs. Temperature light alloys, such as steel , stronger than titanium than other light metals , steel and nickel alloys , and this advantage can be maintained to about 500 º C , so some titanium alloys suitable for manufacturing gas turbine components . surgical implant titanium Approximately 80 percent titanium production for the aviation and aerospace industries. Airframe structural materials such as the U.S. B-1 bomber , the titanium about 21 %, mainly used in the manufacture of the fuselage , wings, skin and bearing components . Airframe structural materials F-15 fighter , the titanium with a capacity of 7000kg, accounting for about 34% of structural weight . Boeing 757 aircraft structural parts , titanium about 5% , with a capacity of 3640kg. McDonnell Douglas (Mc-Donnell-Dounlas) produced DC10 aircraft , titanium with a capacity of 5500kg, accounting for more than 10% of the weight of the structure . The amount of titanium in the chemical and general engineering areas: U.S. , about 15 % of its production in Europe accounts for about 40%. As the excellent corrosion resistance of titanium and its alloys , good mechanical properties , titanium wire as well as qualified histocompatibility make it for the production of biological materials prosthetic devices.

2014年8月7日星期四

Aviation Research and Application of Titanium Alloys titanium bars for sale

Development needs of high-performance aircraft engines pulling the development of high-temperature

titanium alloy, titanium alloy using titanium plate suppliers the temperature gradually increased from the 1950s to the alloy

represented through improved to alloy represented. Currently, representatives of the international

advanced high temperature titanium alloy United States, Britain, Russia and China. Composition and

performance characteristics of high temperature titanium alloy. Problems flame titanium research and

development direction present, except the United States and Russia, some typical titanium retardant

has been applied, the study of other countries on the flame is still in the research phase titanium

alloy, titanium alloy type flame medical grade titanium retardant less costly and flame retardant properties of non-uniform

evaluation methods have hindered the development of fire-retardant titanium. Through research, the

authors believe that the development direction of the flame titanium alloy mainly: (1) development

of uniform standards and methods of evaluation of titanium flame retardant properties. Properly

evaluate flame retardant properties of titanium alloys is one of the key technologies of flame

titanium, titanium alloys, including combustion simulation methods and testing techniques.

Currently, the evaluation method on the flame retardancy is no uniform standard, countries have

adopted different methods of testing. So retardant performance evaluation method to develop a

unified standard titanium will effectively promote the exchange of national retardant titanium. (2)

improve the overall mechanical properties of titanium alloys retardant. Compared with flame

titanium, titanium alloy retardant poor mechanical properties, the working temperature is lower. On

how to further improve the mechanical properties of the alloy of the need for a deeper study. (3)

reduce the flame titanium costs. titanium standard parts Resistant titanium alloy contains a lot of noble metal elements V,

resulting in higher costs, limiting its applications. Domestic scholars have adopted partial

substitution of lower-priced Mo V for a certain amount of research to try.

2014年8月6日星期三

gathered to discuss improvement titanium alloy bar

Titanium prices titanium industry challenged

In the case of the current downturn in the industry, the giant titanium prices still maintained a

good performance. Said that since the outbreak of the international financial crisis, many foreign

companies reduced orders more, but not export giant titanium prices affected. The company

specializes in the production cell equipment. The company has in the country looking for the special

process to produce high quality titanium composite rods. Giant titanium prices have developed

according to the needs of the enterprise to create a high-performance, specifically titanium copper

composite rod, successfully won the national invention patent. Giant titanium prices in the course

of many years of cooperation with the company in the formation of a stable relationship between

supply and demand, so the order has been less affected. "Titanium industry downturn, the general

public products competitive, but we would have developed a differentiation strategy." Giant into

Titanium titanium copper production also obtained a patent, and other enterprises reach the same

level of product technology requirements "if not a few years ago to lay a solid foundation, and now

we are also very difficult." expect recovery to seek future development of the titanium road price

after Baoji Titanium Group hosted the XII World titanium series of activities will be - 2010

international seminar on the Development trends of titanium, inviting national industry experts

gathered to discuss improvement and enhancement of titanium technology. Although titanium industry

in trouble, many people in the industry agree that the next 1-2 years, titanium prices will

stabilize, warmer driven by domestic titanium round bar and external demand, capacity utilization is expected to be a

slow recovery, titanium product prices will also be rebound. Analysts believe that entering 2010,

the international airline industry recovery trend evident, from a global point of view, aviation

titanium with titanium demand accounted for half of the global titanium industry is expected to

bottom out, pick up the recovery. Driven by the global economic recovery, demand for titanium

civilian areas, including chemical, metallurgy, electric power, salt, etc. is also expected to

stabilization and recovery, and promote the recovery of titanium industry. In addition, China's

large aircraft program titanium sheet (large passenger and the Grand Canal), Chang E engineering, rail station

plan, nuclear program, marine engineering (ship manufacturing, offshore oil exploration and

desalination, etc.) as well as the sustainable development of the national economy are on the

titanium and its alloy material of a higher quality and greater quantity requirements. China's

titanium industry has recently introduced the "Twelfth Five-Year Plan" shows that the titanium

industry, "second five" main objectives are: to control titanium sponge and titanium ingot capacity

expansion; improve industrial concentration of titanium, 3-5 to form a world-class big business;

promoting titanium industry energy conservation, energy consumption of titanium sponge the whole

process down to 26,000 kwh / ton; promote industrial structure adjustment, titanium and its alloys

large forgings, extrusions, seamless titanium pipe extruded tubing, titanium and titanium pipe with domestic technology;

effectively promote the export of titanium products, and strive to achieve titanium sponge and

titanium processing material export rate of 30%.

2014年8月5日星期二

Titanium supply specific research strategy titanium bar for sale

Titanium supply specific research strategy

Recently, titanium suppliers titanium industrial bar located in the industrial parks of titanium supplier Co., workers are

annual tons of titanium sponge production line busy. This is currently the only supplier of titanium

sponge production with advanced core technology that enables the whole process of production of

titanium sponge titanium supplier manufacturers. Titanium sponge is the basic raw material for the

production of titanium and titanium titanium sheet alloy products. Titanium and titanium alloy for superior

performance, are widely used in aviation, aerospace, ships, petrochemicals, medical and other

fields, known as the "21st century material" in the context of economic globalization, vendor

selection in the production and operation of enterprises role changes. Titanium supplier selection

is no longer just a single business function, and has gradually become a strategic decision. When

titanium supplier selection has gradually become a corporate strategic decision-making, companies

can no longer choose the traditional titanium wire lowest quality as the main criteria for suppliers, but must

establish a rigorous and comprehensive standards. In this case, how to select and manage suppliers,

many companies have become an urgent need to face and solve the problem.

2014年8月1日星期五

nano-titanium dioxide powder and inorganic antibacterial

100t grade titanium dioxide production base in Suzhou, Anhui completed

An annual production capacity of 100t of titanium dioxide production base in Suzhou City of Anhui has been completed , and fill the gaps in Anhui nano- industrialization . Recently, Anhui Kona New Materials Co., development and production of nano-titanium dioxide powder and inorganic antibacterial powder 2 provincial new product , has passed the appraisal committee of China University of Technology , Chemical Engineering and Materials Science, Academician Qian Yitai nine experts such as identification . Experts agree: This two new nano technology has reached advanced level in our country , is an important step towards the industrialization of nanotechnology forward ; these two high-tech products can be used in sunscreen cosmetics , paints , chemical fiber, plastics , rubber, daily necessities , household appliances , sport and health fields . In the 1980s , foreign companies have started to produce titanium dioxide , currently the world's annual demand in tons . Our cash used in sunscreen cosmetics , chemical , automotive paint and other areas of nano-titanium dioxide powder is almost entirely dependent on imports .

, Represents only the views of the author , and Ben Lichangwuguan . Accuracy of Information Network Information Technology Co., Ltd. Shanghai Nonferrous which does not contain or reference , reliability or completeness of any express or implied warranty. For any direct or indirect result of the use , reprint losses resulting from the information provided herein , Shanghai Nonferrous Network Information Technology Co., Ltd. shall not be liable . Media cooperation , please contact info@smm.cn or 021-61831988 turn 5003 .

2014年7月22日星期二

Pedal Titanium Axle has high strength and density